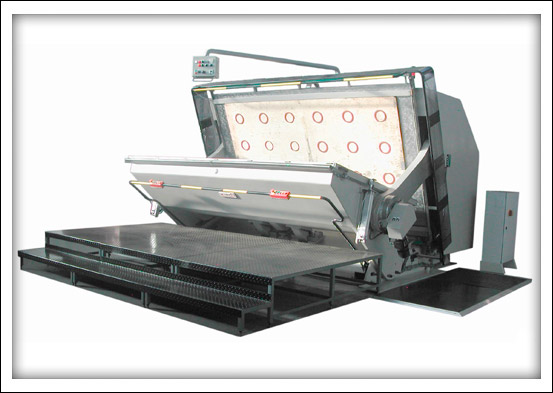

Our clamshell die cutters are designed to die cut

many different types of materials like foam board, laminated board, corrugated board, all types of fine cardboard and paper, kiss-cut adhesive labels, wooden and soft metal sheets and some types of plastics.

We produce a wide range of models and can

build any special size upon demand; we want each customer to have the best suitable clamshell die cutter to meet their needs.

Cauhe clamshell die cutters are sold worldwide and are designed to meet or exceed the Strictest Safety Standards. Our die cutters comply with other country specific safety regulations like ANSI B65.5 in the USA.

The latest addition in safety systems is the

laser scanner. This type of scanner system has been successfully incorporated on our clamshell die cutters since 2000. Placing one laser scanner on each side of the machine prevents access from the sides and placing one unit at the top prevents front access and safely covers the danger zones leaving just a safe gap above the moving platen to feed and deliver the materials keeping the operator safe.

There are several ways to set our clamshell die cutters in position. The most common is to anchor it to the floor by bolts or chemical anchors, but we recommend using

anti-vibration mountings, specially designed for these machines.

They prevent the die cutter from moving away and avoid the vibration produced from each punching stroke, to be transmitted to the company floor. When using anti-vibration mountings, the machine installation is faster as well.

We offer each customer the opportunity to decide where to locate the ma¬chine controls.

These setting controls can be placed in the main cabinet of the clamshell die cutter, in the safety knee bar or on the overhead control panel located above the machine. The overhead control can be moved from side to side to suit the operator’s needs.

With the

electronic speed control unit the machine speed can be adjusted + / - 20% of the rated speed to suit the needs of each job or the capabilities of each operator.

The

automatic lubrication system’s program insures the clamshell die cutter receives the proper amount of lubrication at the scheduled time, allowing the operator to continue working uninterrupted. The system contains sensors to detect low oil and will stop the machine if a no oil or pressure event is detected.

The easily programmed optional

batch counter is equipped with a large digital screen for easy viewing. The counter counts down one sheet per machine stroke from a preset value set by the operator. Once it reaches zero, the system beeps and starts to count down from the preset value again.

Realizing that some of our customers may employ special needs workers, we can manufacture our clamshell die cutters to fit any particular need as well as meet¬ing any specific requirements so that all individuals can work efficiently.

We have a wide range of options to help the operator

lower make-ready time.

- Minimizing the cutting die change over time when starting a new job is possible with our optional automatic chase systems. These systems can be single or double type. The latter allows the cutting die to be moved up or down. It can be operated by a hand wheel, by a pneumatic motor or by an electric motor. We can also manufacture it with a standard chase frame so the frame can be removed to maximize the cutting die size. Any of the above options can be fitted to meet a particular need.

- The pneumatic cutting plate lifter minimizes the make-ready time when setting up a new job. The optional pneumatic cutting plate lifter raises the cutting plate to allow the operator fast and easy access to the setup sheet which speeds up the make-ready process.

- Reduce make-ready time by using the optional sheet band guide system. It is easily adjusted to fit any size sheet.

- One of the most time consuming tasks to perform when setting up a new job is adjusting the cutting pressure. Normally pressure adjustment is performed manually with tools by unlocking and turning the micro-fine eccentric gear and often the operator will need to change the pressure setting several times during each make-ready which consumes valuable time. We provide two options to reduce pressure adjustment time, our exclusive motorized pressure adjustment system and our hand wheel adjustment system. Cauhe is the only clamshell die cutter manufacturer in the world to offer an optional motorized pressure adjustment system. The operator simply presses a but¬ton to raise or lower cutting pressure. Our second option is a hand wheel pressure adjustment system. No tools need for either pressure adjustment system

Our optional

die heating system allows the operator to work with less cutting pressure and at the same time obtain a higher quality finish on many types of plastic, styrene and vinyl materials. Easily programmable heat zone controls allow the operator to rapidly adjust die heater temperature.

Customers that have materials that need to be pre-heated before die cutting

would benefit from our optional second heating unit installed in the moving platen of the clamshell die cutter.

Clients requiring foil stamping capabilities would greatly benefit from our optional

foil stamping system. The foil’s fed from the roller stand at the rear of the clamshell die cutter up to the used foil collection rewind unit located on top of the machine. We can provide as many rewinding units as needed.

Our one touch control screen allows for fast and accurate adjustments for the foil speed and stroke of each individual foil roller.

Our removable

honeycomb plate allows the operator the ability to die cut or foil stamp with one die cutter. Our honeycomb plates are designed to be easily installed or removed for foil stamping or die cutting. We can manufacture the honeycomb plate to fit any kind of automatic chase which allows the operator to fit it as easy and fast as fitting a cutting die.

If you need a clamshell die cutter, contact us, let us know your specific need and requirements and we will make sure we offer you the most suitable die cutter for your purposes.