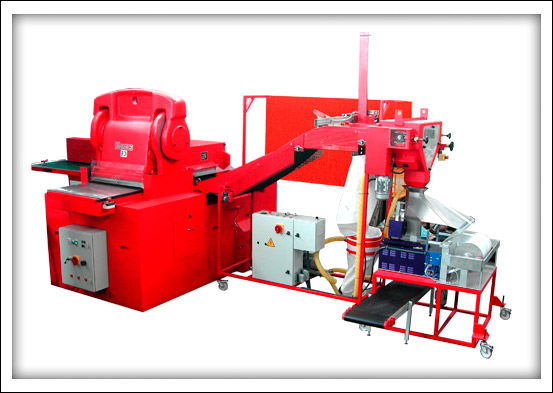

The puzzle die cutter has been specially designed to die cut compact cardboard with puzzle shape die knives.

The material is inserted into the cutting plate to be mechanically introduced inside the press. The puzzle comes out automatically on the back part of the puzzle die cutter to a conveyor belt that leads the die cut puzzle toward the chop up device to dismantle the puzzle. Later, the puzzle pieces go through the bagging and bag sealing system. With this procedure we achieve more productivity in the puzzle die cutter since the front of the machine is only used to feed the material.

Depending on the material to die cut and the operator’s skills, the machine can work on sheet-by-sheet mode or on dwell-timer mode, where the operator sets the times at which the machine will proceed to die cut.

The puzzle die cutter is completely safe covered and is according to CE regulations.

The primary conveyor belt, the chop up device, the bagging system, the missing piece verification, a secondary conveyor belt, are all optional items that can be incorporated to our puzzle die cutters production line.

The complete chop-up device consists on a conveyor belt that transports the die cut puzzle to the system that dismantles it into small pieces. After that, it can be taken to the bag sealer and packed into a plastic bag. The bagging can also be executed manually. The missing piece verification system is easy to regulate on each job and detects when one piece did not come out of the puzzle die cutter when die cut.

Along with the bagging system, a label code printing machine can be incorporated to the puzzle die cutter production line. The machine will print a reference on each puzzle bag. A high precision weight can also be integrated to control incomplete puzzle bags.

The frame extractor system is very useful for companies that do not guillotine the material prior to die cut the puzzle. The system removes the frame while the die cut puzzle travels in the conveyor belt and it dismisses the frame out of the production line.

When a puzzle is too big to be die cut in one stroke, it can be done in 2 strokes. For this purpose, a semi-diecut stacker can be incorporated which will accomplish an easier handling of the material.

When high production is required, there are several ways to achieve it:

- By incorporating an automatic feeder to the puzzle die cutter

- For customers who wish to die cut puzzles in only one stroke, the puzzle die cutter can be reinforced

- Double feeding system is also another option to increase production substantially.

Any other option or need the customer may have, it will be studied by our team and incorporated into the puzzle die cutter to meet all your production line requirements.